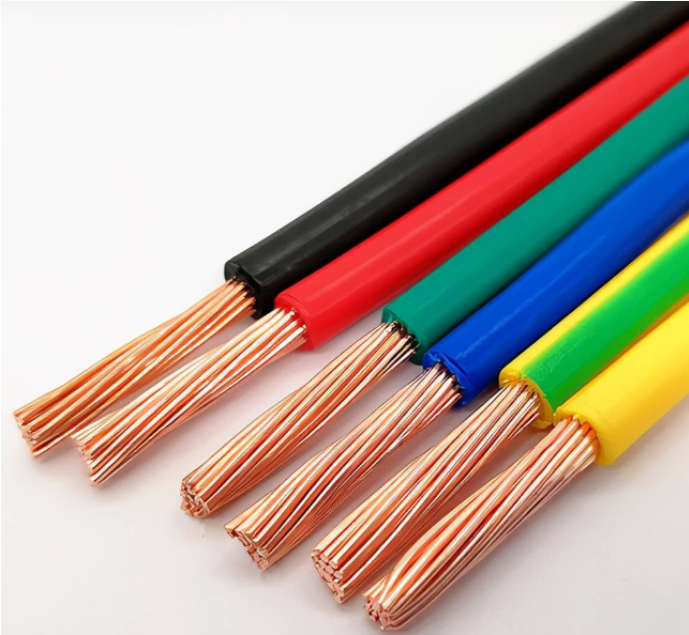

When it comes to installation, the choice between flexible wires and rigid wires plays a crucial role in ensuring the safety, efficiency, and durability of electrical systems. Flexible wires, as the name suggests, are designed with multiple strands of thin conductors, allowing them to bend and twist easily. This characteristic makes them ideal for applications where frequent movement or routing through tight spaces is required, such as in portable electronics, automotive wiring, or installations involving complex layouts. Their flexibility also simplifies the installation process, reducing the risk of damage to the insulation or conductors during handling. On the other hand, rigid wires typically consist of a single solid conductor, offering greater mechanical strength and stability. They are commonly used in fixed installations where minimal movement is expected, such as in building wiring, power distribution panels, or overhead power lines. Rigid wires excel in environments that require consistent conductivity and can withstand higher mechanical stress, making them a reliable choice for long-term, stationary applications. Understanding the differences between flexible and rigid wires is essential for selecting the right solution for specific installation needs, as it directly impacts the performance and longevity of the electrical system.