Core Differences in Insulation Materials for Indoor vs. Outdoor Power Cables

Why environmental conditions dictate different insulation requirements

Power cables used inside buildings versus those installed outside deal with completely different issues. Inside spaces, the main job of insulation is stopping electricity from leaking out while also holding up against small amounts of physical damage. But when cables are placed outdoors, they have to handle much harsher conditions including sun damage, super cold or hot weather ranging from minus 40 degrees Celsius all the way up to 90 degrees, dampness, and contact with various chemicals. Take regular PVC for example it breaks down about three times quicker when exposed to sunlight because the molecules start falling apart. That's something mentioned in the latest NEC 2023 standards actually. Given these big differences between indoor and outdoor environments, picking the right materials becomes absolutely critical if we want our wiring systems to last over time without constant replacement.

Material science fundamentals: Flexibility, durability, and environmental resistance

| Property | Indoor Priority | Outdoor Priority |

|---|---|---|

| Flexibility | High (ease of routing) | Moderate (sheath focus) |

| UV Resistance | Minimal | Critical |

| Hydrolysis Resistance | Low | High (IP68 compliance) |

Thermoplastics like PVC dominate indoor applications due to their flexibility and low cost. In contrast, cross-linked polyethylene (XLPE) is preferred outdoors because its molecular structure resists degradation from heat, moisture, and UV radiation, offering superior durability in harsh conditions.

Case study: Failure of indoor-rated cables used outdoors

A 2023 field study analyzing 1,200 installations found that 63% of indoor-rated cables failed within 18 months when deployed outdoors. Primary failure modes included insulation cracking (42%), conductor corrosion (29%), and dielectric breakdown (19%). These results highlight the significant risks of using materials not engineered for external environments.

Strategy: Matching power cable insulation to application environment

To optimize performance and longevity, follow a three-step protocol:

- Identify exposure risks (UV, moisture, chemicals)

- Verify temperature ratings against local climate extremes

- Prioritize cross-linked materials for outdoor runs exceeding 15 meters

This proactive approach minimizes premature failures and ensures regulatory compliance.

Industry trend: Rising adoption of cross-linked polymers for outdoor resilience

XLPE now accounts for 58% of new outdoor power cable installations, up from 34% in 2018. Its dominance stems from a proven 30-year service life in severe climates—nearly triple that of PVC, which typically lasts only 8–12 years outdoors. This shift reflects growing recognition of XLPE’s resilience and lifecycle cost advantages.

Weather and UV Resistance in Outdoor Power Cable Insulation

Withstanding Rain, Snow, and Freeze-Thaw Cycles: Long-Term Durability Needs

Cables used outdoors need to stay pliable even when temperatures drop to -40 degrees Celsius and should not become brittle after repeated freezing and thawing. The latest data from the Outdoor Infrastructure Report for 2025 shows something interesting about cable jackets. Cables wrapped in thermoplastic elastomer (TPE) had roughly 9 out of 10 fewer insulation problems over five years in cold northern areas than regular PVC cables do. That kind of reliability explains why many installers are turning to TPE and cross-linked polyethylene (XLPE) materials for projects in places where winters get really harsh. These materials just handle extreme cold better because they maintain their structural integrity longer under those tough conditions.

Moisture Barriers and Humidity-Resistant Material Designs

Moisture intrusion causes 34% of outdoor cable failures (IEEE Standard 1215-2023). XLPE’s hydrophobic molecular structure effectively repels water, while multi-layer constructions incorporating conductive polymer moisture-blocking tapes reduce humidity-related conductivity losses by 74%. These features are essential for underground or high-humidity installations.

UV Degradation Mechanisms and Sunlight Exposure Risks

UV radiation breaks down hydrocarbon bonds in insulation, leading to brittleness and reduced dielectric strength. Accelerated aging tests show unprotected PVC loses 80% of its tensile strength after 2,000 hours of UV exposure—equivalent to about 18 months in desert conditions. Without proper protection, this degradation compromises both safety and functionality.

Additives and Polymer Choices for Superior UV Protection

Manufacturers enhance UV resistance using carbon-black-stabilized XLPE and additives like benzotriazoles. These formulations extend cable lifespan by 50% in tropical zones and maintain dielectric performance with less than 0.5% annual loss even under full solar irradiance. Such advancements make modern outdoor cables far more resilient than earlier generations.

Thermal Performance and Temperature Ratings of Insulation Materials

Temperature Stability in Fluctuating Indoor and Outdoor Climates

Cables work in all sorts of conditions, from nice steady indoor spots where temperatures only change around 20 degrees Celsius to harsh outdoor areas where temps can swing more than 70 degrees in a single day. The special insulation used outdoors has to handle everything from freezing cold below minus 40 degrees right up to scorching heat above 90 degrees. That's an amazing temperature range of about 130 degrees, which is roughly four times what regular indoor cables need to deal with. Keeping these cables working properly through such extreme conditions matters a lot because nobody wants their power supply cut off when it matters most.

Performance Comparison: XLPE vs. EPR in High-Heat Environments

Cross-linked polyethylene (XLPE) outperforms ethylene propylene rubber (EPR) under sustained heat:

| Material | Continuous Rating | Short-Circuit Withstand | Aging (15-year projection) |

|---|---|---|---|

| XLPE | 90°C | 250°C for 5 sec | —12% tensile strength loss |

| EPR | 105°C | 200°C for 10 sec | —25% tensile strength loss |

While EPR offers higher continuous ratings, XLPE maintains better dielectric stability above 90°C, making it preferable for buried cables near heat sources such as transformers or industrial equipment.

Reference Standard: NEC Table 310.104(A) on Allowable Temperature Ratings

According to the National Electrical Code®, outdoor cables need at least a 75°C insulation rating while standard indoor cables only require 60°C. That extra 25% accounts for things like sun exposure, nearby equipment generating heat, and unexpected power surges during emergencies. Real world experience shows big benefits too. Engineers who follow NEC Table 310.104(A) see about 43% less problems with insulation breaking down early, based on numbers from the NFPA in their 2022 report. Something important to remember is selecting insulation that can handle maximum temperatures rather than just average conditions. When done right, this approach stops around two thirds of all thermal issues before they happen, as found in Duke Energy's analysis from last year looking at actual installations across different climates.

Chemical Exposure and Environmental Stress Resistance

Outdoor insulation challenges: Pollutants, oils, and industrial runoff

Cables used outdoors encounter much harsher chemical conditions compared to those inside buildings. They deal with all sorts of stuff like leftover fuel, acid from rainwater mixing with road grime, and various air pollutants. These concentrated messes tend to break down insulation faster, sometimes cutting its lifespan by around 40%. Regular polyethylene or PE tends to swell and develop tiny cracks when it comes into contact with oil products. That's why cross-linked polyethylene (XLPE) works better in tough environments. Its special thermoset construction doesn't deform as easily and keeps its electrical properties intact, which makes XLPE the preferred choice for places where cables get exposed to industrial chemicals or city pollution.

Balancing eco-friendly biodegradable materials with long-term reliability

In lab tests following ASTM D5511-18 standards, biodegradable insulation breaks down about 97% quicker than synthetic alternatives. But there's a catch when these materials meet real world conditions like moisture and pollution, which can compromise their reliability over time. On the flip side, researchers have developed hybrid materials by mixing PLA bio resins with special UV stabilizers. Field trials show these combinations last around 15 years before needing replacement, matching what we typically see from standard PVC insulation. What makes this even better is the environmental benefit: production creates roughly 62% less carbon emissions compared to traditional methods. For manufacturers looking at both sustainability and product longevity, these new composite materials offer some genuinely exciting possibilities for future cable designs.

Real-world data: ASTM D2219-20 for wet-environment performance benchmarks

ASTM D2219-20 testing highlights key differences in water immersion performance:

| Material | 90-Day Water Immersion | Dielectric Strength Loss |

|---|---|---|

| Standard PVC | 23% swelling | 37% reduction |

| Hydro-resistant XLPE | 4% dimensional change | 8% reduction |

| These metrics validate XLPE’s superiority in flood-prone or submerged applications, where resistance to electrochemical treeing and long-term dimensional stability are critical. |

Common Insulation Materials Compared: PVC, PE, XLPE, EPR, and Silicone Rubber

Properties and use cases of PVC, PE, XLPE, EPR, and silicone rubber

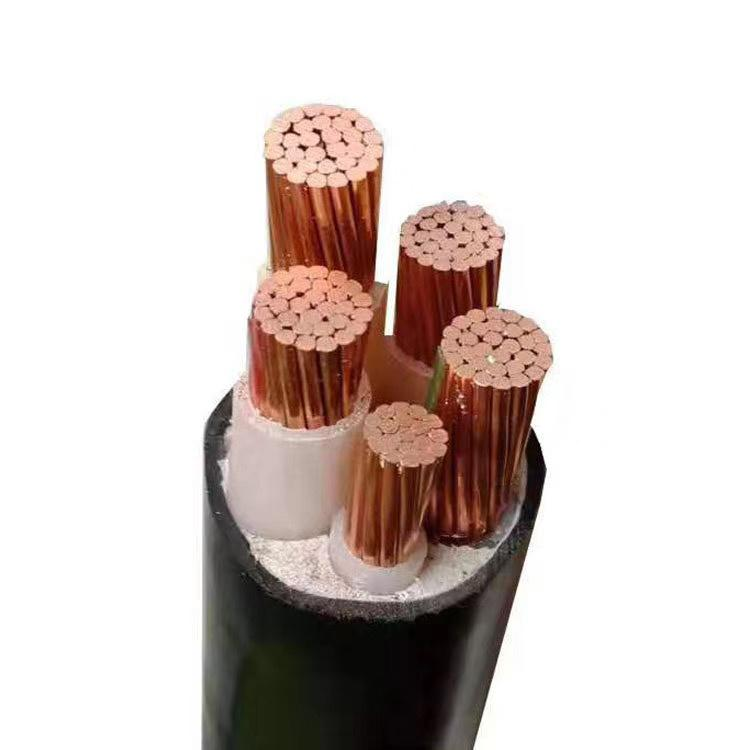

PVC is still pretty common inside buildings because it bends easily, doesn't catch fire so readily, and costs less than many alternatives. It works well in temperatures ranging from about minus 40 degrees Celsius all the way up to around 70 degrees. PE material keeps things dry really well, but gets too stiff when temps drop below minus 20, which makes it not so great for outside installations. XLPE takes things further, allowing operation from as cold as minus 55 right up to 90 degrees Celsius, plus it handles UV exposure better and stands up to physical stress much better too. That's why we see it frequently in places like solar panel fields and power line networks. EPR stays flexible even at minus 50 down to 150 degrees, so it's often found in moving parts such as those big spinning blades on windmills. Silicone rubber can handle crazy hot conditions up to 230 degrees Celsius, which is why foundries and other industrial operations rely on it despite needing extra protection layers since it isn't as strong under tension compared to some other materials.

| Material | Temperature Range | Key Strength | Common Application |

|---|---|---|---|

| PVC | -40°C to 70°C | Cost efficiency | Indoor control panels |

| XLPE | -55°C to 90°C | UV resistance | Outdoor power distribution |

| Silicone | -60°C to 230°C | Heat tolerance | Steel mill feeders |

Thermoplastics vs. thermosets: Structural and longevity differences

Materials like PVC and PE fall into the thermoplastic category, which means they can melt down and reshape again. This makes them pretty convenient for installation work and repairs when something breaks. The downside? Leave these materials in hot conditions for too long and they start to warp or deform. On the other side of things we have thermosets such as XLPE and EPR. These materials create those permanent cross links once cured, giving them much better durability. In tough environments where regular plastics would fail, thermosets last way longer. Take XLPE for instance. After sitting outside for 25 whole years, it still holds onto about 92% of its original dielectric strength according to ASTM D2219-20 standards. Standard PE only manages around 67% after the same time frame. Sure, thermosets cost roughly 30 to 40 percent more initially, but think about all those saved dollars on maintenance calls and replacements over time. Many industrial facilities find this tradeoff well worth it in the long run.

Application-specific selection: Indoor wiring vs. outdoor power cables

When looking at indoor cabling solutions, manufacturers focus more on how flexible they can be bent around corners and their ability to withstand fires rather than worrying about weather protection. For outdoor installations though, different requirements come into play. Materials such as cross-linked polyethylene (XLPE) become necessary because they stand up better against water breakdown, which is really critical when cables are laid underground near sources of groundwater. According to recent field reports dating back to last year, those XLPE insulated cables actually had about 80 something percent fewer problems related to moisture compared to regular polyethylene ones used in similar environments along coastlines. And speaking of extreme environments, down in the Arctic Circle where temperatures regularly drop below minus 60 degrees Celsius, special silicone rubber insulation keeps oil rig equipment from cracking even though these materials cost roughly triple what standard XLPE would normally set someone back.

Lifecycle cost analysis: Initial price versus service life and maintenance

PVC runs around $0.18 per foot while XLPE is pricier at about $0.35 per foot. But here's the catch: outdoor PVC usually needs replacing somewhere between 7 to 12 years down the road. XLPE? That stuff can stick around for 25 to 40 years before needing attention. When looking at what things cost over 30 years, XLPE actually comes out cheaper by roughly 37%. There's also EPR to consider. Priced at $0.28 per foot, EPR lasts about 35 years and works pretty well in places where conditions aren't too harsh but still challenging, such as those wastewater treatment facilities we all rely on. The bottom line? Don't get tricked by upfront prices alone. Think long term when making these decisions because smarter choices now lead to safer systems and savings later on.

FAQs

Why do indoor and outdoor cables require different insulation materials?

Indoor and outdoor cables are exposed to vastly different environmental conditions. Indoor cables primarily deal with minor electrical leak prevention and physical damage, while outdoor cables face UV radiation, moisture, harsh temperatures, and chemicals, necessitating different insulation characteristics for durability and efficiency.

What makes XLPE a preferred material for outdoor power cables?

XLPE is favored for outdoor applications due to its excellent resistance to UV radiation, moisture, heat, and physical stress. Its hydrophobic molecular structure and durability make it suitable for harsh outdoor environments, as it maintains structural integrity and resists degradation far better than alternatives like PVC.

What happens if indoor-rated cables are used outdoors?

Using indoor-rated cables outdoors can lead to premature failures, such as insulation cracking, conductor corrosion, and dielectric breakdown, due to their inability to withstand the harsh outdoor conditions. These failures highlight the importance of selecting the right materials for the application environment.

Are biodegradable insulation materials reliable for long-term use?

While biodegradable materials decompose much faster than traditional materials, real-world exposure to elements like moisture and pollutants can compromise their reliability. Hybrid materials combining PLA bio resins with UV stabilizers offer a more balanced solution, providing sustainability and extended service life.

Table of Contents

-

Core Differences in Insulation Materials for Indoor vs. Outdoor Power Cables

- Why environmental conditions dictate different insulation requirements

- Material science fundamentals: Flexibility, durability, and environmental resistance

- Case study: Failure of indoor-rated cables used outdoors

- Strategy: Matching power cable insulation to application environment

- Industry trend: Rising adoption of cross-linked polymers for outdoor resilience

- Weather and UV Resistance in Outdoor Power Cable Insulation

- Thermal Performance and Temperature Ratings of Insulation Materials

- Chemical Exposure and Environmental Stress Resistance

- Common Insulation Materials Compared: PVC, PE, XLPE, EPR, and Silicone Rubber

- FAQs