In just a few years, engineers have asked for more flexible mineral wires as smarter gear goes online and the push for cleaner energy gets louder. These wires are tough yet bendable, so they keep popping up in places like solar farms, factory robots, and high-rise job sites around the world. Below, we look at the fresh tech behind them, the perks they offer, and where they might lead the wiring business next.

Exceptional Durability and Adaptability

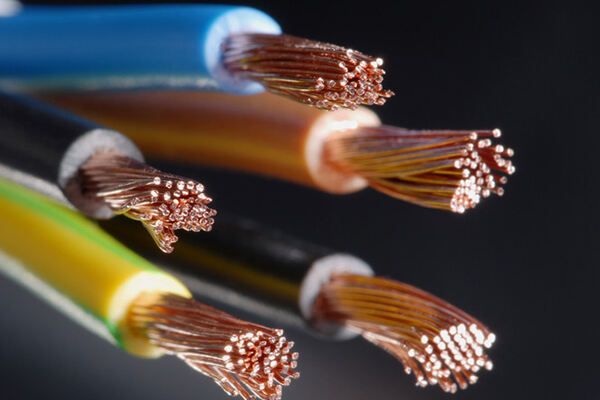

Flexible mineral cables stay strong even when the heat is on or the machine keeps moving. Where older wiring is often stiff and cracks after one twist, the newer mineral version bends freely without losing signals. That kind of agility matters in tight rooms, outside towers, or over walls full of sharp corners. By swapping standard coating for mineral insulation, makers give the line better fire ratings and tougher shielding, so it can run safely in places other cables leave to metal trays.

Integration of Smart Technology

One of the coolest upgrades in flexible mineral cables these days is the addition of smart technology. Unlike older cables, these new lines can track their own performance and send live data to operators on the other end. Because of that, crews can perform predictive maintenance instead of waiting for a break. Built-in sensors watch temperature, pressure, and other key readings so any small problem can be fixed long before it turns serious.

Eco-Friendly Design and Production

Attention to the planet is also shaping the way these cables are designed and built. Makers now experiment with greener materials and cleaner production steps, aiming to slash each cable s carbon footprint. Many are even sourcing recycled compounds and using eco-friendly processes that line up with the world s climate goals. That move protects natural resources and gives customers the greener option they increasingly ask for.

Expanding Applications in High-Tech Scenarios

Flexible mineral cables are finding new uses as workplaces and project sites grow more high-tech. In renewable energy, they hook up solar panels and wind turbines, channeling power with minimal loss. Factories rely on them to support automated lines, speeding production while reducing downtime. Even construction teams choose these cables because the lightweight, tough design fits cramped or exposed areas.

Future Outlook for Flexible Mineral Cable Technology

The outlook for the technology is bright. Engineers are already testing compounds that bend more easily and resist harsher chemicals, while smarter insulation lowers conductance losses. As companies push toward greener operations, flexible mineral cables are likely to wire the next wave of efficient machines and grids.

In short, miniaturized circuits keep reliability high without extra bulk, giving modern engineers a cable they can trust in demanding environments. With every improvement, they move us closer to safer, leaner work sites and a more resilient energy system.