Control cables play a key role in industrial automation, acting as the link for both data and power in all kinds of tasks. This blog post looks at how the right cables can boost efficiency, dependability, and safety in automated factories.

What Control Cables Do

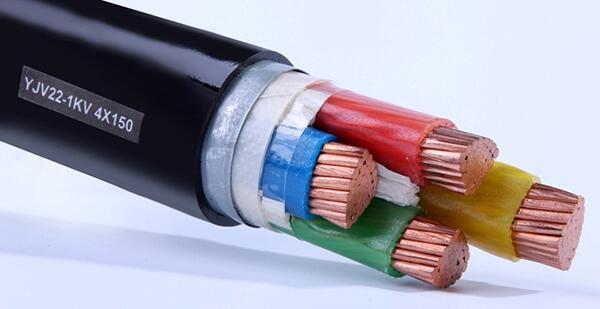

Control cables carry signals and power from one part of an automated system to another. You’ll find shielded and unshielded versions, each made for a specific job. Choosing the right cable truly affects the entire system. A stable connection means signals reach their targets correctly and without noise, which keeps production lines and robots running smoothly.

Boosting Efficiency

The biggest payoff from good control cables is faster, leaner operations. Quality cables lose less signal and turn down less interference, letting data zoom between machines and controllers. This speed is vital for apps that need real-time updates, like robotic arms or high-speed assembly lines. Clear, speedy communication cuts delays and keeps machines online, which can speed up production and lower costs, so businesses see a jump in the bottom line.

Keeping Industry Safe and Dependable

Control cables do more than just speed things up—they’re key to keeping industrial processes safe and dependable. To work where conditions are tough, manufacturers build cables with tough insulation and shielding that keep out moisture, chemicals, and rough handling. This kind of strength is a must where machines deal with grit, spills, and constant vibration. A dependable control cable that stays strong also guards against signals fading, a problem that can cause machines to glitch and create dangerous surprises. When companies choose top-grade cables, they cut risks and boost workplace safety right across the facility.

The Next Wave of Control Cable Tech

New technology is driving a fresh wave of control cable designs. The latest cables are lighter, more flexible, and run easier through the twisting pipes and racks of a busy factory. Another leap is the smart cable, which has tiny built-in sensors that track how the cable is behaving. These sensors offer live updates on the cable’s condition, allowing teams to spot trouble before it happens and schedule maintenance at the safest time. The result is fewer unexpected stops and a greener operation—because cables that last longer and run cooler mean less waste and lower energy use.

The Future of Control Cables in Automation

As machine facilities keep leveling up their automation game, there’s no slowing down on the need for smarter control cables. The next wave of cables will spotlight greener ingredients and low-energy designs, so production lines can save power before the cables even get plugged in. On top of that, packing cables with IoT tech is set to supercharge their role, giving every connection a tiny sensor that shares temperature, wear, and signal info on the fly. Early adopters that plug in now can squeeze the most out of robots, conveyors, and pick-and-place systems down the road.

Wrap it up, and control cables are the unsung wiring heroes behind smoother factory floors. They slash downtime, protect workers, and keep devices in sync by being one step ahead of tech change. Industry players who cue in on the latest cable twists in material, sensor, or design will keep their automation humming and gain an edge on the competition. Whether it’s copper, fiber, or biodegradables, the cable choice can move the whole automation strategy up one more gear.