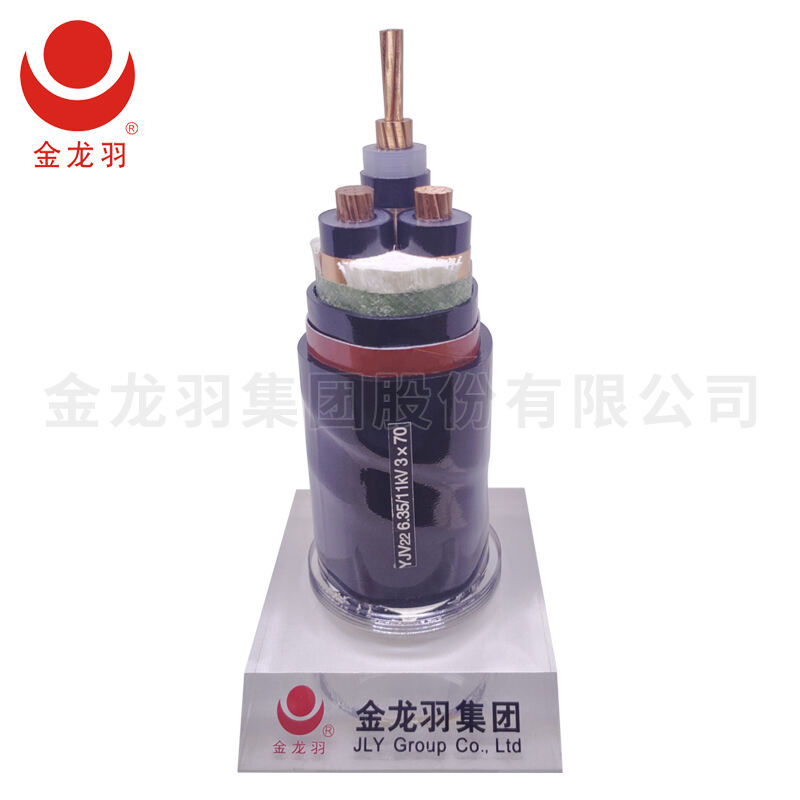

บริษัท เว่ยตง เทคโนโลยี เป็นผู้ผลิตสายส่งพลังงานไฟฟ้าที่มีฉนวนหุ้มประสิทธิภาพสูง ซึ่งได้รับการออกแบบมาเพื่อส่งพลังงานไฟฟ้าอย่างปลอดภัยและมีประสิทธิภาพ ป้องกันการรั่วของกระแสไฟฟ้า และรับประกันความปลอดภัยของผู้ปฏิบัติงาน สายส่งพลังงานไฟฟ้าที่มีฉนวนหุ้มเหล่านี้มีแกนกลางทำจากตัวนำไฟฟ้าที่มีความนำไฟฟ้าสูงอย่างทองแดงหรืออลูมิเนียม ล้อมรอบด้วยชั้นฉนวนที่แข็งแรงผลิตจากวัสดุ เช่น พอลิเอทิลีนเชื่อมโยงขวาง (XLPE), PVC หรือกระดาษซับน้ำมัน ซึ่งให้ความแข็งแรงของฉนวนไฟฟ้าที่ยอดเยี่ยมเพื่อทนต่อแรงดันไฟฟ้าสูงโดยไม่เกิดการทะลุ ฉนวนในสายส่งพลังงานไฟฟ้าที่มีฉนวนหุ้มมีความสำคัญอย่างมากในการป้องกันการลัดวงจรและปกป้องระบบจากปัจจัยแวดล้อมต่าง ๆ เช่น ความชื้น สารเคมี และความร้อน ทำให้เหมาะสำหรับการติดตั้งทั้งแบบเหนือดินและใต้ดิน ขึ้นอยู่กับการใช้งาน สายส่งพลังงานที่มีฉนวนหุ้มอาจประกอบด้วยชั้นเพิ่มเติม เช่น ชั้นกันไฟฟ้าสถิตเพื่อกระจายแรงดันไฟฟ้าอย่างสม่ำเสมอ ชิลด์โลหะเพื่อควบคุมสัญญาณรบกวนทางแม่เหล็กไฟฟ้า และชั้นหุ้มด้านนอกเพื่อปกป้องเชิงกล สายส่งพลังงานไฟฟ้าที่มีฉนวนหุ้มของ Weidong มีให้เลือกหลายระดับแรงดันไฟฟ้า ตั้งแต่ 1 กิโลโวลต์สำหรับระบบจ่ายไฟในท้องถิ่น ไปจนถึง 500 กิโลโวลต์สำหรับการส่งไฟฟ้าระยะไกล โดยทั้งหมดได้รับการทดสอบเพื่อให้เป็นไปตามมาตรฐานที่เข้มงวดสำหรับความต้านทานฉนวนและความเสถียรทางความร้อน ด้วยคุณสมบัติการเป็นฉนวนที่เชื่อถือได้ สายส่งพลังงานไฟฟ้าที่มีฉนวนหุ้มเหล่านี้มีบทบาทสำคัญในการรักษาความปลอดภัยและประสิทธิภาพของระบบไฟฟ้ากำลัง