How UV Exposure and Extreme Weather Affect Construction Engineering Wires and Cables

Wires and cables used for outdoor construction projects tend to degrade much faster when they're constantly hit by UV rays, deal with temperature changes over 60 degrees Celsius (which is around 140 Fahrenheit), and operate in areas where humidity stays above 85%. According to research published in the 2025 edition of Polymer Degradation Studies, exposure to sunlight can cut down on the tensile strength of polyethylene insulation by roughly 38% after just 18 months because of photo-oxidation. When moisture gets into these systems in really humid conditions, it starts breaking down PVC materials through hydrolysis processes. This actually weakens how well the material resists electrical currents, sometimes dropping dielectric strength by as much as 22% each year. And let's not forget about those temperature swings either. The constant heating and cooling makes multi-conductor cables expand and contract repeatedly, which creates stress points along their length. Field technicians report seeing cracks form at cable bends about 35% more often than expected under normal operating conditions.

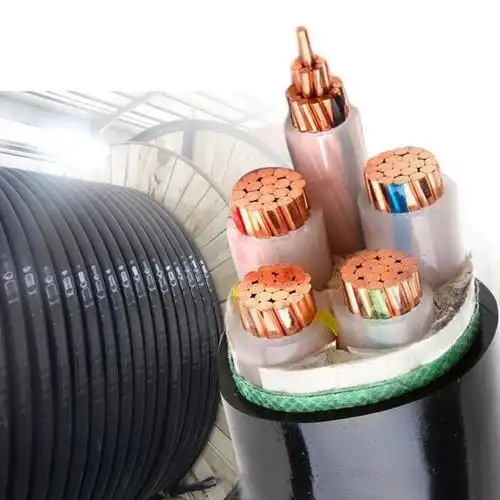

Role of Insulation Materials Like XLPE in Enhancing Environmental Durability

When it comes to outdoor electrical insulation, cross linked polyethylene or XLPE beats regular PVC hands down. The main reasons? Well, XLPE can handle temperatures up to around 120 degrees Celsius thanks to its special molecular makeup that repels water. After spending 5,000 hours under UV lights following those IEC 60502-1 tests, XLPE keeps about 92% of what makes it strong mechanically. Regular PVC only holds onto about two thirds of its strength after similar testing. What really matters though is how XLPE's unique polymer structure cuts down on moisture pickup by roughly 40%, plus it won't crack even when temps drop below freezing point all the way to minus 40 degrees. That's why engineers often specify XLPE for things like bridge wiring systems and equipment installed near coastlines where conditions are tough on materials.

Selecting Cable Jackets and Barriers Based on Climate Zones and Installation Conditions

Cable jacket selection must align with regional climate threats:

| Climate Challenge | Recommended Jacket Material | Key Benefit |

|---|---|---|

| Desert UV Exposure | Polyethylene with carbon black | Blocks 98% UV radiation |

| Coastal Salt/Moisture | Chlorosulfonated Polyethylene | Resists chloride-induced corrosion |

| Arctic Thermal Cycling | Silicone Rubber | Maintains flexibility at -60°C |

In high-rainfall zones, anti-tracking jackets with hydrophobic additives help prevent surface leakage currents. Direct-buried cables in freeze-thaw regions should be installed in HDPE conduits with 200% elongation capacity to accommodate ground movement.

Mechanical Strength and Flexibility for Reliable Outdoor Performance

Impact of Physical Stress During Installation and Service Life on Cables

During installation, construction engineering wires face bending stresses well above 25 Newtons per square millimeter. Buried applications typically see compression forces going beyond 1,500 pounds per square inch according to ASTM D1248 standards. Materials such as cross linked polyethylene (XLPE) are known for reaching tensile strengths of about 220 megapascals. These materials hold their shape even when dragged through tight conduits or subjected to pressure from surrounding rock fill. Looking at real world performance data reveals something interesting. Cables that manage to keep at least 90 percent of their initial diameter after spending five years underground last significantly longer than what most industry guidelines predict. Some studies indicate these cables outperform expected lifespans by roughly 40 percent.

Balancing Flexibility with Abrasion, Impact, and Crush Resistance

Optimal cable designs use hybrid jacketing—Shore A 85–90 hardness rubber for flexibility combined with nylon overbraids that offer 300% improved abrasion resistance. Materials with a flexural modulus of 12–15 GPa (per ISO 178) support tight bending radii down to 6xD while withstanding 50 J impact energy levels, protecting against rock impingement.

Use of Armored UF-B and OSP Cables for Direct Burial and High-Risk Applications

Armored UF-B cables feature galvanized steel tape meeting UL 1277 crush resistance standards (3,000 lbs/ft²). OSP (Outside Plant) cables incorporate fiberglass yarn reinforcements that absorb 15–25% more impact energy than unarmored variants. These solutions prevent insulation breaches in high-traffic areas and locations prone to excavation damage.

Flame Retardant and Low Smoke Performance in Outdoor Fire Safety

Fire Risks Associated with Outdoor Electrical Installations Near Buildings

Outdoor cables near structures pose elevated fire risks due to proximity to flammable building materials and ventilation pathways. Aging insulation at cable entry points accounts for 34% of outdoor electrical fires, where heat sources ignite combustible jackets and release toxic smoke (Ponemon 2023).

Technology Behind Flame Retardant Additives and Low Smoke Zero Halogen (LSZH) Materials

LSZH materials cut down on smoke production by about 40% and stop those nasty corrosive gases from being released when burned, unlike regular old PVC cables. The magic happens because phosphorus compounds create these protective char layers on the surface, and aluminum trihydrate actually soaks up some of the intense heat as it breaks down. What's really impressive is how LSZH cables keep their circuits working even after sitting in flames at around 840 degrees Celsius for well over half an hour. That kind of performance matters a lot for fire safety systems where people need reliable power during emergencies. Looking at current trends across Europe, roughly seven out of ten industrial cables installed today are going halogen free, showing just how much this technology has taken hold in recent years.

Compliance with CPR Classification and EN50575 for EU Market Access

The CPR Regulation Euroclass B2ca-s1d0 certification basically means that cables won't catch fire easily and produce less smoke, keeping it under 50% density for at least twenty minutes. According to EN50575 standards, independent labs need to test how fast flames spread, how much heat gets released during burning, and whether dangerous droplets form when materials melt. These tests get even tougher for areas where people need to evacuate quickly, like corridors rated Class Cca/S1b. Anyone installing electrical systems should always check those official Declarations of Performance documents and stick to products marked with CPR labels. This isn't just good practice but actually required under the EU Directive 305/2011, so compliance is essential for anyone working on building projects across Europe.

Electrical Performance and Signal Integrity in Harsh Outdoor Environments

Construction engineering wires and cables must maintain consistent electrical performance despite extreme temperatures, moisture, and electromagnetic interference (EMI)—critical for reliable power delivery and data transmission in industrial and transportation infrastructure.

Challenges of Electromagnetic Interference on Unshielded Control Cables

Unshielded control cables in outdoor settings are vulnerable to EMI from power lines, machinery, and lightning. This interference distorts analog signals, leading to data errors or system failures. In high-EMI zones, unshielded cables can experience signal degradation exceeding 40%, compromising operational safety.

Importance of Shielding and Hybrid Power-Data Cable Designs

To mitigate EMI, manufacturers employ braided copper shields, aluminum foil barriers, and twisted-pair configurations that neutralize electromagnetic fields. Hybrid cables integrating power conductors with fiber-optic strands minimize cross-interference and maintain signal clarity over long distances. Premium designs achieve less than 3% voltage drop across 500-meter spans.

Maintaining Signal Reliability in Industrial and Exposed Outdoor Settings

UV-resistant insulation and hermetically sealed connectors prevent moisture ingress in wet environments. For temperature extremes (-40°C to 90°C), XLPE insulation ensures stable dielectric properties. Installers should select cables compliant with IEC 60502-1 and NEC Article 725, which validate performance under mechanical stress and thermal cycling.

Standards Compliance and Installation Best Practices for Longevity

Outdoor-rated construction engineering wires and cables require third-party certifications such as UL 1072 (medium-voltage), CSA C22.2, and IEC 60502 to verify resilience under environmental stress. These certifications confirm resistance to UV exposure, temperature extremes (-40°C to 90°C), abrasion, and dielectric breakdown over decades of service.

Key Certifications for Outdoor-Rated Construction Engineering Wires and Cables

Manufacturers face two main compliance hurdles when it comes to cable performance. First, they need to follow NEC Article 310.15(B)(3)(c) which deals with how electrical current ratings drop off in hotter environments across the United States. Then there's the European standard EN50575 with its various Euroclass ratings such as B2ca-s1,d0,a1 that address fire safety concerns on the continent. To prove their products can withstand real world conditions, independent testing facilities including Intertek and TÜV Rheinland run extensive accelerated aging experiments. These typically involve subjecting materials to over 1,000 hours of intense UV radiation and harsh salt spray conditions, all designed to replicate what cables would experience during approximately 25 years outdoors in tough climates.

Meeting National and International Standards Including NEC, CPR, and EN50575

Harmonizing NEC conductor sizing rules with CPR’s material traceability reduces errors in cross-border projects. CPR mandates batch-specific labeling of LSZH compounds to ensure smoke toxicity compliance, while NEC 2023 updates require 10% larger conduit diameters for bundled outdoor cables to manage heat buildup.

Proper Handling, Conduit Use, and Installation Techniques to Maximize Durability

To prevent kinks when unspooling cables, keep the bend radius at least eight times the cable's diameter. Desert areas call for UV resistant PVC conduits while salt air eats away at regular materials so corrosion inhibited metal works better along coasts. When burying cables directly underground, laying down sand bedding plus warning tape cuts down on crush damage somewhere around 60% according to IEEE standards from 2020. Don't forget those slack loops either spaced about three meters apart to handle temperature changes throughout seasons. Many installations skip this step entirely which explains why nearly 4 out of 10 early cable failures happen, as noted in the latest NFPA guidelines from 2023.

Frequently Asked Questions

What is XLPE insulation and why is it preferred for outdoor electrical installations?

XLPE, or cross-linked polyethylene, is preferred for outdoor electrical installations because it can withstand higher temperatures, resist moisture, and maintain mechanical strength over prolonged exposure to harsh environmental conditions. It is especially favored for its ability to remain intact in temperatures ranging from -40°C to 120°C.

How do flame retardant additives work in cables?

Flame retardant additives work by creating protective char layers on cable surfaces, which prevent the spread of fire and reduce smoke production. Phosphorus compounds and aluminum trihydrate in LSZH materials help absorb heat and form these protective barriers.

Why is compliance with the CPR Regulation important for cable installation in the EU?

Compliance with the CPR Regulation ensures cables are fire-resistant and produce minimal smoke, which is critical for safety during fires. It mandates rigorous testing to verify these properties, making sure installations meet fire safety standards in the EU.

Table of Contents

- How UV Exposure and Extreme Weather Affect Construction Engineering Wires and Cables

- Role of Insulation Materials Like XLPE in Enhancing Environmental Durability

- Selecting Cable Jackets and Barriers Based on Climate Zones and Installation Conditions

- Mechanical Strength and Flexibility for Reliable Outdoor Performance

- Flame Retardant and Low Smoke Performance in Outdoor Fire Safety

- Electrical Performance and Signal Integrity in Harsh Outdoor Environments

- Standards Compliance and Installation Best Practices for Longevity

- Frequently Asked Questions