High-temperature cables matter any time heat threatens sensitive equipment. Built with tough materials, these wires keep signals flowing even in molten-metal factories and engine rooms that glow red-hot, as well as in oil-drilling rigs. Their ability to shrug off blast-furnace air lets plant operators trust systems while the world looks on. In the sections below, we unpack how these heat-proof wires guard people and gear, where they show up, and how fresh designs are narrowing safety margins even further.

Factories thrive on speed, and nothing stops work faster than a burnt-out wire. Spark, smoke, and suddenly costly downtime can turn the day upside down. By swapping standard cable for a high-temp version, engineers snuff that risk.

High-temperature cables are used in all kinds of heavy jobs and the list keeps growing. In factories, you will find them running inside ovens, kilns, and big furnaces. The oil and gas teams rely on them in deep drilling and downhole pumps, where heat and pressure work overtime. Power plants lean on these wires around turbines and generators, because a single meltdown can cause costly shutdowns. With such wide chores to cover, high-temp cables have become a must-have for almost every tough industry.

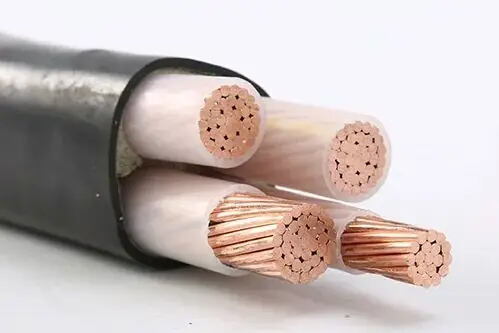

Manufacturers keep pushing boundaries, so cable makers have advanced the science behind high-temp wire. New insulation blends like silicone rubber or fluoropolymer now handle hotter air while staying bend-friendly on the job. These materials shrug off sparks, chemicals, and ozone that would crack older jackets, keeping copper safe longer. Because of that, repair teams spend less time crawling into hard spots and plant managers notice smaller bills over years. Simply put, smarter insulation equals fewer outages and better peace of mind in the field.

On the safety front, new rules are coming in fast and thick, pushing factories and plants to take fewer chances with heat. Now, in places where wires might sit beside roaring furnaces or Baker tanks, watchdogs expect managers to choose high-temperature cables and nothing less. Many engineers see this not as a headache but as a good nudge that gets their bosses to open the purse and upgrade. Because of stricter checks and a clearer cost-benefit picture, experts predict the market for heat-resilient wire will climb, pulling with it fresh designs and smarter materials.

In short, if a production line runs hot, the right cable makes a world of difference, turning possible failure into routine reliability. These wires shrug off flame, steam, and melting-jacket tests, so they keep motors and control boxes humming where ordinary insulation falls apart. As tools shrink, speeds rise, and codes grow tougher, the need for gear that never quits even in a furnace-like zone will only swell. Businesses that track the latest high-temp wires, swap older stock on schedule, and fit the right grade to every job will shield people, cut downtime, and guard the bottom line for years to come.