Understanding the Role of Visual Inspection in Assessing Electrical Equipment Wires and Cables

The Importance of Visual Inspection in Quality Control for Electrical Equipment Wires and Cables

Looking things over visually remains one of the best ways to catch problems before they become serious safety issues in electrical systems. According to NFPA data from 2023, this simple check can spot around three out of four manufacturing flaws and installation mistakes long before any actual failure happens. When workers examine cables and connections, they look at things like whether insulation is intact, if wires are properly aligned, and if labels are clear enough to read. These basic observations help catch poor quality components or workmanship early on. Factories that make regular visual inspections part of their routine tend to see roughly 35% fewer days when equipment sits idle because of breakdowns, compared to places where technicians only fix things after something goes wrong.

Key Principles of Visual Inspection Techniques for Detecting Early-Stage Cable Degradation

Effective inspections follow three core principles:

- Controlled lighting: Use 500-1000 lux illumination to reveal hairline cracks or discoloration

- Systematic evaluation: Examine cables segment-by-segment from connector to termination point

- Reference benchmarks: Compare findings against MIL-STD-202G specifications for acceptable surface irregularities

These practices allow technicians to detect micro-abrasions in insulation—often harbingers of insulation resistance failure up to 18 months in advance.

Common Surface-Level Indicators of Compromised Wire Integrity

Eight visual red flags account for 92% of quality-related wire failures. Among the most critical are:

| Defect Type | Failure Risk Increase |

|---|---|

| Partial sheath cracking | 3.8x |

| Conductor discoloration | 2.1x |

| Fading compliance marks | 4.5x |

Technicians prioritize these during walkdown inspections, recognizing that a single compromised wire can lead to system-wide failure within six months of deployment.

Evaluating Sheath and Conductor Appearance for Quality Defects

Visual Evaluation Methods for Cable Sheath and Conductor Condition

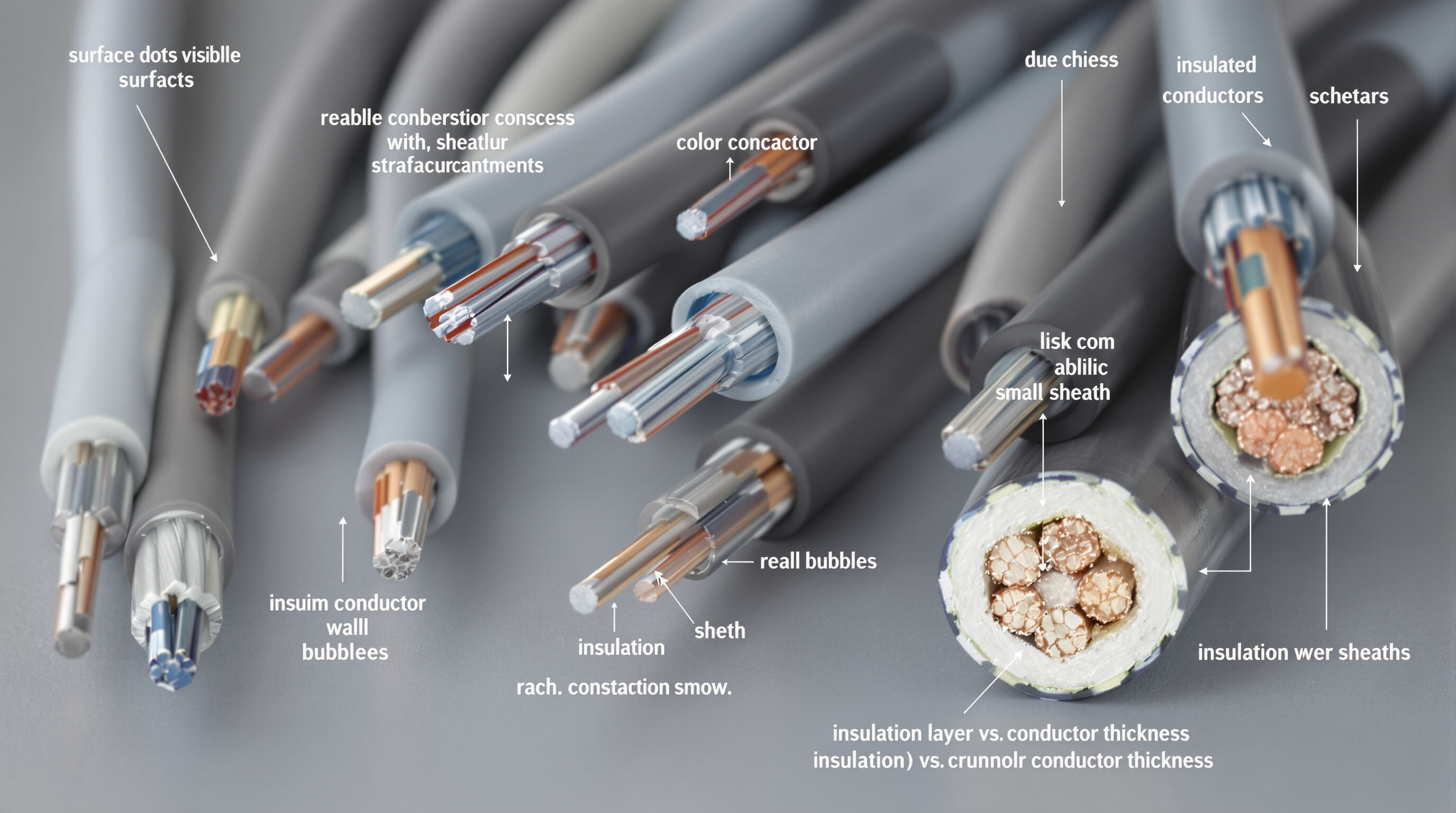

Start checking the cable's outer covering when there's good light available. Quality cables should have a consistent color all around, feel smooth to the touch, and display clear markings. They won't show variations in thickness either, so watch out for any visible seams or bubbles trapped inside the material. When looking at the conductors themselves, it's worth getting closer with some magnification. A rough surface means trouble - things like small pits, strands that don't lie flat together, or signs of rust are red flags pointing toward cheap materials. Taking a cross section view can tell us a lot too. The ratio between the protective layer and actual conductor needs to be right for safety reasons. Industrial grade cables generally need at least 1.5 times more insulation compared to conductor size to stay within safe limits.

Identifying Signs of Poor Quality: Damage, Discoloration, and Inconsistent Labeling

Key warning signs include:

- Thermal Stress: Yellowish-brown discoloration near terminations

- Mechanical Damage: Abrasions exceeding 10% of sheath thickness

- Labeling Irregularities: Faded text or mismatched codes between labels and jacket printing

Cables with visible abrasions fail 23% faster under load testing than undamaged counterparts, highlighting the impact of surface damage on dielectric strength.

Case Study: Detecting Cracked Insulation and Exposed Conductors in Substandard Cables

In an infrastructure check last year, engineers found out that problems with the lighting system kept happening because of tiny cracks in the insulation that everyone thought were just surface issues at first. When they looked closer, these cracks actually went through about 8 out of 10 parts of the insulation layer, letting water get to the wires inside. What this shows is that regular inspections need better lighting angles if we want to spot hidden damage that normal lights just can't reveal. A lot of these issues stay undetected until something goes wrong, which is why proper inspection techniques matter so much for maintenance work.

Differentiating Aesthetic Flaws From Functional Defects in Cable Sheaths

While minor scuffs may not affect performance, certain defects require immediate rejection:

- Concentricity Issues: Off-center conductors reducing effective insulation

- Thermoplastic Deformation: Wavy sheathing indicating improper extrusion cooling

- Interrupted Shieldings: Gaps in metallic shields visible at cut ends

Inspections should focus on high-stress zones—terminations, bends, and connection points—where defects are most likely to escalate into failures.

Detecting Early Signs of Wire Degradation Through Visual Clues

Visible Indicators of Wire Degradation: Cracking, Chafing, Heat Damage, and Fluid Exposure

Signs of early wear usually show up visually first. Look for things like cracks in the insulation, places where it's rubbed thin, those brownish spots that appear when wires get too hot (anything over 90 degrees Celsius really does the trick), or sections that look swollen because they've been exposed to moisture. These problems mean the structure is starting to break down and actually lead to about a third of all insulation failures in damp areas according to industry data. Techs working on site need to pay special attention to bends in cables and connection points since most of the initial damage happens there. We're talking around 70 percent of cases start at these vulnerable spots as noted in the latest NFPA guidelines from 2023.

Assessing Insulation Integrity Under Environmental Stress Through Appearance

Environmental stress accelerates aging. Evaluate insulation using these indicators:

| Stress Factor | Visual Warning Sign | Action Threshold |

|---|---|---|

| UV Exposure | Fading/chalky texture | >20% color loss |

| Chemical Contact | Surface tackiness/blistering | Any visible deformity |

| Thermal Cycling | Longitudinal micro-cracks | >3 cracks per inch |

Field Strategy: Routine Checks for Heat-Induced Discoloration and Brittleness

Conduct monthly inspections in heat-prone areas. Perform fingernail tests on suspect insulation—material that crumbles indicates advanced polymer breakdown. Darkened copper conductors suggest sustained overload, requiring immediate load balancing per industrial safety guidelines.

Emerging Trend: Non-Contact Visual Monitoring of Cable Condition in Industrial Settings

Advanced facilities now use hyperspectral imaging (350-2500 nm wavelength range) to detect subsurface degradation invisible to the naked eye. This non-contact method identifies early thermal stress patterns with 94% accuracy, reducing unplanned downtime by 41% in continuous operations (IEEE Transactions on Industrial Informatics 2023).

Verifying Manufacturer Labeling and Compliance Markings for Authenticity

Why Manufacturer Information and Labeling Are Critical for Traceability and Safety

Accurate labeling enables traceability during recalls and safety audits. Legible manufacturer names, batch codes, and production dates are essential. In industrial settings, blurred or incomplete markings increase maintenance costs by 20% (IEEE 2023) due to extended troubleshooting efforts.

How to Visually Verify Compliance Markings and Conductor Specifications

Inspect cable jackets for embossed or printed certifications like UL, CE, or RoHS. Confirm legibility using a magnifier and cross-check with manufacturer documentation. Measure conductor diameter—deviations over 5% from labeled specs often indicate substandard materials.

Data Insight: 68% of Counterfeit Cables Lack Proper Certification Labels (Source: IEEE 2022)

Industry surveys show 34% of counterfeit cables feature falsified UL logos, while 29% omit flame-retardant ratings. In high-risk environments like data centers, missing NFPA 70E arc-flash warnings correlate with a 40% higher incident rate (Electrical Safety Foundation 2023).

Best Practices for Identifying Fake or Non-Compliant Electrical Equipment Wires and Cables

- Use UV lights to detect tamper-evident features in certification labels

- Verify holographic seals on high-voltage cables

- Compare insulation thickness against ANSI/NEMA WC 66 standards

- Reject batches with inconsistent font styles—a common sign of counterfeiting

These checks should be performed during delivery acceptance, as 78% of non-compliant cables enter systems through unchecked shipments (NFPA 2023).

Assessing Physical Integrity: Flexibility, Structure, and Assembly Quality

Evaluating Flexibility and Structural Soundness During Installation Inspections

Perform three-point bend tests during installation to assess flexibility. High-quality wires maintain integrity when bent to their minimum radius (typically 6-8 outer diameter). Key indicators include:

- Smooth bending without kinking

- Consistent sheath elasticity

- No visible conductor deformation

Common Issues in Low-Quality Wires: Stiffness, Kinking, and Internal Strand Breakage

Excessive rigidity often signals poor copper annealing or oxidation. Recent audits attribute 23% of premature failures to internal strand fractures, which remain undetectable without destructive testing.

Bend Testing as a Practical Field Method for Assessing Cable Durability

A standardized protocol includes:

- Wrapping the cable around a mandrel matching manufacturer-specified bend radius

- Inspecting for sheath cracks under 5 magnification

- Measuring post-test resistance changes (₹¥10% increase indicates degradation)

Visual Inspection of Cable Assemblies and Harnesses in Manufacturing and Maintenance

Assembly defects contribute to 41% of warranty claims in power distribution systems. Focus on:

- Uniform wire lay within bundles

- Proper grommet installation at entry points

- Absence of twisted or crossed conductors

Crimp Quality and Connection Integrity: Preventing Failures Through Pre-Assembly Checks

High-resolution borescopes enable verification of:

- Complete conductor capture in terminals

- Correct placement of insulation supports

- Smooth, concentric crimp profiles

Industry Standard: MIL-STD-202G Guidelines for Harness Visual Inspection

MIL-STD-202G requires 100% inspection of critical power cables for:

- Sheath discoloration exceeding 15% surface area

- Marker legibility under 50 lux lighting

- Strain relief engagement depth

FAQ

Why is visual inspection important for electrical equipment wires and cables?

Visual inspection is crucial for catching manufacturing flaws and installation mistakes early, reducing potential safety hazards and downtime due to equipment failure.

What are common visual clues of wire degradation?

Indicators include cracks in insulation, chafing, heat damage, fluid exposure, and discoloration near terminations.

How can I verify the authenticity of electrical wire compliance labels?

Use magnification to check legibility and confirm embossed or printed certifications like UL, CE, or RoHS against manufacturer documentation.

What factors contribute to wire failure?

Factors include partial sheath cracking, conductor discoloration, and improper labeling, leading to increased failure risks.

Table of Contents

- Understanding the Role of Visual Inspection in Assessing Electrical Equipment Wires and Cables

-

Evaluating Sheath and Conductor Appearance for Quality Defects

- Visual Evaluation Methods for Cable Sheath and Conductor Condition

- Identifying Signs of Poor Quality: Damage, Discoloration, and Inconsistent Labeling

- Case Study: Detecting Cracked Insulation and Exposed Conductors in Substandard Cables

- Differentiating Aesthetic Flaws From Functional Defects in Cable Sheaths

-

Detecting Early Signs of Wire Degradation Through Visual Clues

- Visible Indicators of Wire Degradation: Cracking, Chafing, Heat Damage, and Fluid Exposure

- Assessing Insulation Integrity Under Environmental Stress Through Appearance

- Field Strategy: Routine Checks for Heat-Induced Discoloration and Brittleness

- Emerging Trend: Non-Contact Visual Monitoring of Cable Condition in Industrial Settings

-

Verifying Manufacturer Labeling and Compliance Markings for Authenticity

- Why Manufacturer Information and Labeling Are Critical for Traceability and Safety

- How to Visually Verify Compliance Markings and Conductor Specifications

- Data Insight: 68% of Counterfeit Cables Lack Proper Certification Labels (Source: IEEE 2022)

- Best Practices for Identifying Fake or Non-Compliant Electrical Equipment Wires and Cables

-

Assessing Physical Integrity: Flexibility, Structure, and Assembly Quality

- Evaluating Flexibility and Structural Soundness During Installation Inspections

- Common Issues in Low-Quality Wires: Stiffness, Kinking, and Internal Strand Breakage

- Bend Testing as a Practical Field Method for Assessing Cable Durability

- Visual Inspection of Cable Assemblies and Harnesses in Manufacturing and Maintenance

- Crimp Quality and Connection Integrity: Preventing Failures Through Pre-Assembly Checks

- Industry Standard: MIL-STD-202G Guidelines for Harness Visual Inspection

- FAQ