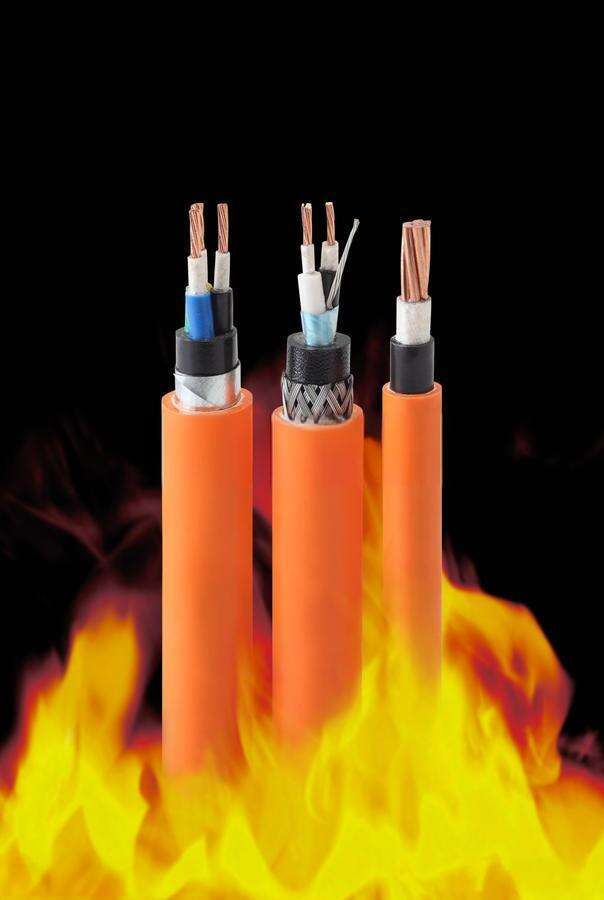

Understanding how to choose electrical cables for projects is crucial for ensuring safety, efficiency, and cost-effectiveness, and Weidong Technology provides a structured approach based on project requirements. The first step in how to choose electrical cables for projects is defining the application—residential wiring may need flexible BVR cables, while industrial projects require heavy-duty armored cables. When learning how to choose electrical cables for projects, calculate the current load and voltage to select the right conductor size and insulation rating, as undersized cables risk overheating. Environmental factors play a key role in how to choose electrical cables for projects: outdoor use demands UV-resistant, waterproof cables, while high-temperature areas need silicone-insulated options. Another factor in how to choose electrical cables for projects is compliance with local standards (e.g., GB, IEC) to ensure regulatory approval, with Weidong’s cables clearly marked for easy verification. Additionally, how to choose electrical cables for projects involves considering installation needs—stranded cables for tight bends, solid-core for fixed runs—and long-term durability to reduce maintenance costs. By following these steps on how to choose electrical cables for projects, users can select the optimal solution for any residential, commercial, or industrial application.